Pecka

Mini crust optimizer ZEFIR I

Categories: Cleaning coins, finds , Elektronické konstrukce

And since it is sown everywhere, the crops are growing like water and the fields have not been searchable for some time, I started to clean up the small coins from previous catches.

The biggest problem is the stone crust, formed by the settled clay soil, which cannot be removed in any other way than mechanically. This is always quite a problem because mechanical cleaning always leaves some grooves on the coin, so I try to avoid this method of cleaning. For the worst crust and at the end of the cleaning, an ultrasonic bath can be used for a short time, but in any case this method of cleaning is not suitable for frequent and repeated use.

Electrolysis is certainly not a cure-all, for classic coin cleaning the tried and tested means are amply sufficient. For Agka chelaton III or citric acid, coppers can be cleaned very well in oxalic acid. I take electrolysis as a necessary evil for removing the worst deposits on found coins, which the classical methods cannot cope with. Chemistry won't get the crust off the coin.

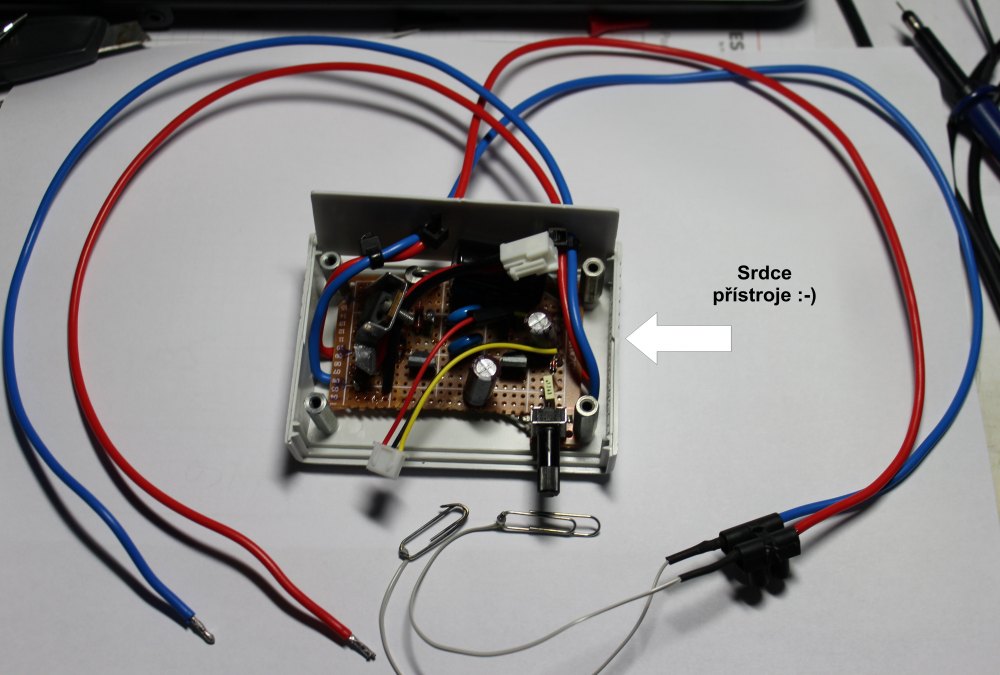

For the actual electrolysis, you can use a DC power supply with a regulated voltage, or just a transformer withdiodes and a simple output voltage control, in which case a simple pulsed power supply is also available. I'm sure everyone owns an unnecessary adapter or power supply that can be used for electrolysis quite easily. I was treating a vintage complex and came across the wiring of a swept multivibrator in an AR 04/19. The wiring can also be used for electrolysis mainly because of the smearing, where at the lowest level of regulation it behaves as a frequency source and generates a rectangle and when the resistance on P1 is increased it gradually goes to DC voltage.

It's cleaning for a long time, the brave can use a DC source with a fixed voltage, but the results may not be very good. If it is consistently monitored, then yes.

On the cleaning itself. I leave the coin in a saturated chelaton III solution for about 2 hours preferably on the heater, if the crust loosens then I clean carefully. If not I stir the chelaton solution and attach the decruster. Input voltage is 12-20V, output rectangle 4-10V, current draw about 50-60mA, so zero to nothing, it's really very weak and the characteristic of the above multivibrator is quite suitable for electrolysis. I continuously rotate the coin and rinse it with water. The crust slowly starts to fall off. Cleaning takes a maximum of two hours. If the coin does not come off, I immerse it in water overnight and repeat the electrolysis cleaning the next day in a weak chelating or salt solution, or in tap water alone.

Then only carefully with the chelaton, rather only in water. Small coins such as Gresle and kreuzers do not contain much silver (about 30 max 50%) and the coin may start to turn red.

This method of cleaning works although it is a bit tedious. I have another version of the crust destructor in mind with timing that will periodically send a stronger pulse. Changing the frequency occasionally isn't a bad thing either, possibly reversing the polarity and making the coin a positive electrode for a moment. It's more than that and it's a long shot. Anyway, something else will surely be developed in the future.

The article is included in categories: