Tak to si šílenec já bih se chtěl taky vrátit k pájce před dvaceti leti sem si taky dost hrál ale pakpřišlo bouřlivé životný obdobi a bilo vše jinak špatně samozřejmě

Krusta destructor V0

Categories: Cleaning coins, finds , Elektronické konstrukce

Since there has been quite a bit of free time lately, and it looks like there still will be, as grain and other crops, successfulare rotting in the fields because of the rain, I've gotten around to completing an electrolysis designed to remove crust from badges, medals, coins and similar finds.

I don't know if this post belongs here at all, but there's quite a bit of stuff popping up from other fields, various toy movies, etc. so I'll give it a try too. There's at least one bastler here, I'm sure, because I've chatted with him here, so hopefully this will serve as a resource for my own design and for other people who are into electronics. If this is already out of place, I'll ask admin to delete it.

I was interested in an article in AR4/2019 some time ago

https://www.lovecpokladu.cz/klub/a/mini-krust-optimizer-zefir-i-19511

where the author adapted a circuit from the Russian magazine Radio 5/1985. the basis is a multivibrator that changes its frequency by changing the voltage in the negative branch. Originally it excited a piezo and imitated a siren, it can also be used as a frequency source for electrolysis without much trouble, after replacing the original Mosfet with a BUZ-11.

The advantage of the circuit is that by changing the voltage in the negative branch, you can change the frequency and voltage at the output using the RC component.

It has its limitations, but it has cleaned a lot of small coins with low silver content in the alloy and still works to general satisfaction.

Eventually I needed a regulated DC voltage source for cleaning coppers and also a pulse source for cleaning Aglets with measurements.

Coin cleaning by electrolysis initially came about as a necessary evil to remove crust from copper coins, copper alloy coins, and various badges and awards that I found using a metal detector. In time I found that a similar method could be used to remove crust from small coins with low silver content in the alloy, such as the grechels and kreuzers of Leopold I, etc. Unfortunately, I do not live in an area with sandy soil where one can find crustless coins with perfect patina, hence the following amateur construction.

Electrolytic cleaning deprives the finds of patina, which in some cases can be added. Therefore, consider this method of cleaning and use electrolysis only when absolutely necessary.

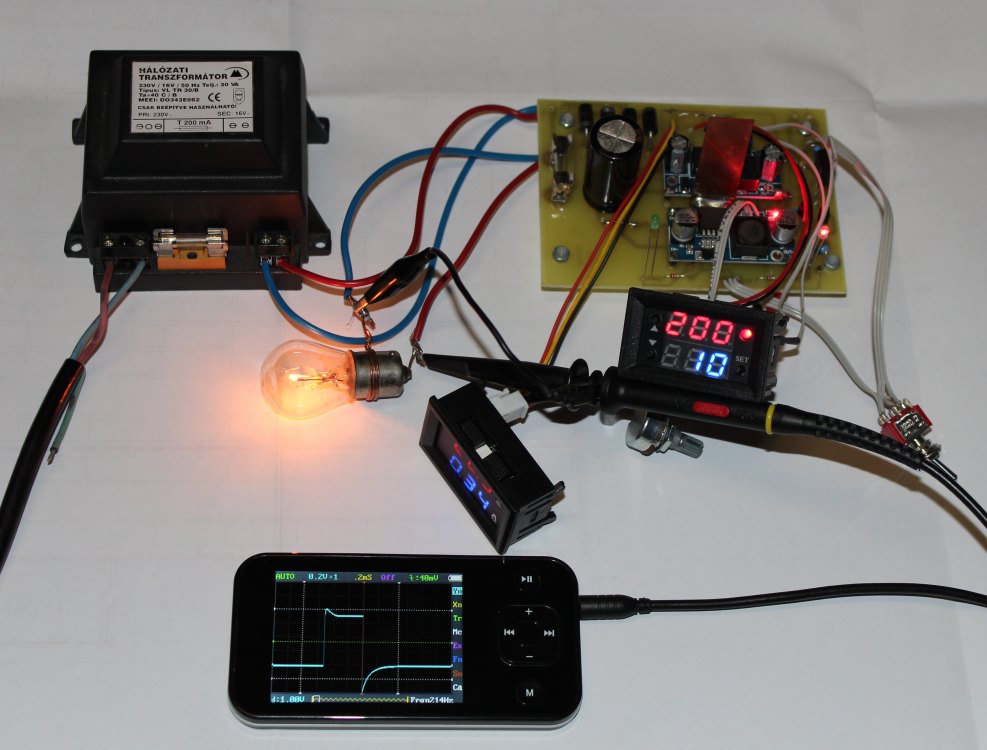

A couple of small things about the measurements, the values displayed are not absolute or mean values measured with a lab meter. They are rather indicative values measured by sampling individual modules. For a basic display of values, this is quite sufficient. If you want to get closer to the real thing, just supplement e.g. the voltmeters with diode rectifiers with filtering. I would rather see the advantage in synchronization, peak detection and averaging of the measured values. This will have to be worked on over time. Also, there may be some errors in the design, for which I apologize in advance.

About the actual electrolysis. This is not the classic wiring shown on wikipedia, it needs to be wired backwards. You connect a cleaned object to the - pole and an electrode made of some soft material to the + pole. Folded tinfoil has worked well for me. There is material loss at the + pole and that is counterproductive in this case. I am not a chemist and therefore am not able to describe the chemical reaction that occurs, but electrodes made of various hard metals or stainless steel did not lead to the desired result. In the case of the stainless electrodes, the electrolyte took on a green hue and the crust did not break off at all.

The current drawn from the source depends on the size of the object to be cleaned and the cleaning method chosen. For copper coins of the size of 3 Francis II coins, the current drawn should not exceed 1A. For small kreuzers and half kreuzers 600mA. For small AG coins 100-200mA and preferably in pulse mode or with additional periodic timing. Also the cleaning method is different due to the materials. For coppers, DC is sufficient, where the crust breaks off after a few tens of minutes, then drying and subsequent wax preservation is sufficient. After preservation, the coin just needs to be heated with a heat gun and you're done.

It's different for small Agecas. For the actual cleaning, I leave the coin for 2-3 hours in a chelaton III solution. Heating will also help the result by hastening the chemical reaction. I have a resistor preheater for this, which can also be connected to the crust destructor described later. If the crust cannot be removed, I attach the crust destructor to the coin and ideally the crust will break off or begin to dissolve. If not, I repeat the whole procedure. You can't do this indefinitely because the chemistry used makes the copper come to the surface. If it doesn't work the first time, I give it a second try at most and then leave the coin as is.

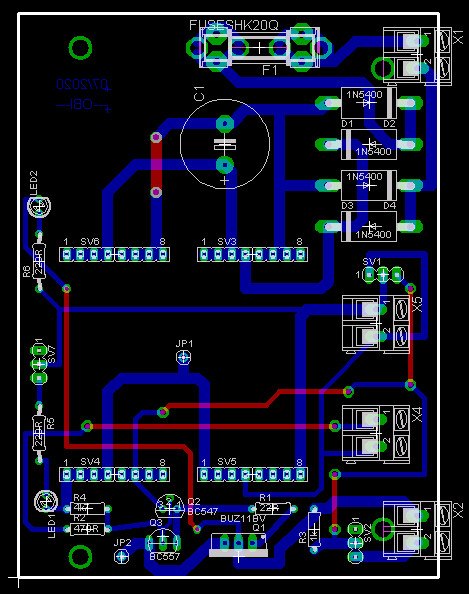

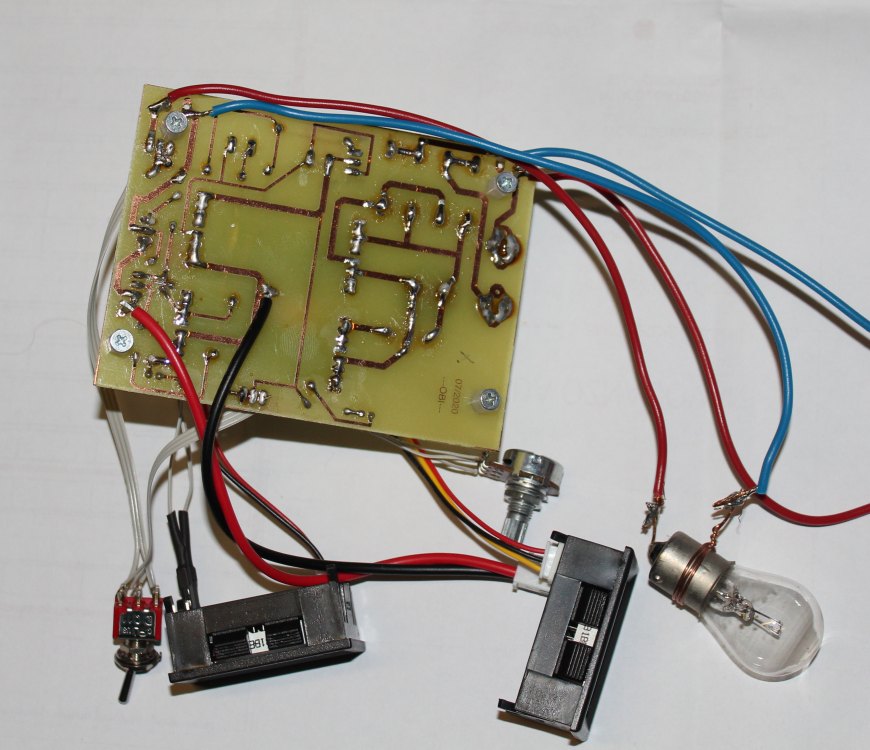

Krusta destructor

Krusta destructor is a universal voltage regulated power supply and PWM controller. It contains a voltage source and is used to destroy the crust of both copper coins and small AG coins with a silver content of about 0.3 in the alloy. The base modules are two DC-DC converter modules with LM2596 circuits supplemented by a V/A meter and PWM regulation and a terminal stage consisting of complementary transistors and a BUZ11 mosfet. One converter serves as a current source for electrolysis, so it is necessary to replace the original trimmer with a 10k potentiometer. It is advisable to solder a heat sink consisting of a copper strip to the LM2596 and solder the same to the BUZ11. The second converter is used to power the V/A meter and the PWM generator that drives the final stage.

Wiring is not complicated, just be careful when buying DC-DC converters. I bought about 10 of them for development and testing, and about half worked in real life. I've shopped variously, Auction, Aliexpress etc.... Everything was wrapped in the original foil and the result is unfortunately what it is. It is worth to test everything on the table before soldering the modules to the PCB. Also the dimensions of the modules vary quite a bit due to HW revisions. I don't have it sealed in a box yet, who is to drill and carve with it. Maybe it will stay in the shoebox :-) So far, it has cleaned a few coins, tests, short circuits and burn-in are in progress and it looks like it could work in the long run without major problems.

If you want to build this experiment, here is a link to save.to:

https://ulozto.cz/tamhle/b4invzpDroIK#!ZGAyAmR1AzVlMzV4LwL5ZwWvLGuwF0yipxSSoJ9cMSuxBGHj

It's not the final version yet, the timer will still need to be tweaked. I don't know if it will be a module for this design, or if a new one will be created where the measuring modules will be dropped and it will all be equipped with one display....

It's mainly because of the small Ag coins. It should work by starting the electrolysis in pulse mode with minimal power, then the whole thing shuts down for a few tens of minutes to hours, and then repeats the whole process. The idea is to torture the coins with as little chemistry and current as possible.

It's still a long way off, but why not give it a try.

If anyone manages to modify this idea or design, or move it somewhere I'd be happy to. In fact, that's why this article was written.

Good luck colleagues.

Here's a breakdown of the parts used:

Partlist

Exported from Krusta_destruktor_V0.sch at 30.09.2020 13:15:01

EAGLE Version 4.16 Copyright (c) 1988-2005 CadSoft

Part Value Device Package Library Sheet

C1 2200uF/35V CPOL-EUE7.5-16 E7,5-16 rcl 1

D1 1N5400 DO201-15 diode-1 1

D2 1N5400 DO201-15 diode-1 1

D3 1N5400 1N5400 DO201-15 diode-1 1

D4 1N5400 1N5400 DO201-15 diode-1 1

F1 FUSESHK20Q FUSESHK20Q SHK20Q fuse 1

- PCB fuse wire

LED1 LED3MM LED3MM led 1

LED2 LED3MM LED3MM led 1

Wire led 3mm 2x

Q1 BUZ11BV BUZ11BV TO220BV transistor-power 1

Q2 BC547 BC547 TO92 transistor-npn 1

Q3 BC557 BC557TO92-EBC transistor-pnp 1

R1 22R R-EU_0207/7 0207/7 rcl 1

R2 470R R-EU_0207/7 0207/7 rcl 1

R3 1k R-EU_0207/7 0207/7 rcl 1

R4 4k7 R-EU_0207/7 0207/7 rcl 1

R5 220R R-EU_0207/10 0207/10 rcl 1

R6 220R R-EU_0207/10 0207/10 rcl 1

-Flexo cord 230V

-2x Banana blue, red

-Round 230V switch

-Double lever switch

-Potentiometer 10K/N

-Fuses 2A

-Fuse wire for PCB

-V/A meter module

-PWM generator module

-Kradex Z112J box

The article is included in categories:

- Archive of articles > Tutorials and History Hunters Magazine > Cleaning coins, finds

- Archive of articles > Tutorials and History Hunters Magazine > Elektronické konstrukce

Post

Jj dřif frčeli tranzistory integráky kondíky smeroví dijody potenciometry atd vše tesla vše sem ziskával s televizí rádyjí atd nekupovalo se nic

pájky mam furt knihy mladý radioamatér snad někde taky asi si něco postavim taky zas

pájky mam furt knihy mladý radioamatér snad někde taky asi si něco postavim taky zas

Krystalky to bili časi

Obi - přesně takové návody patří na hlavní stránku. Ačkoliv netuším o čem píšeš, moc se mě to líbí a na éru - Urob si sám - moc rád vzpomínám.

Kdysi dávno jsme dle - Urob si sám - stavěli rotační sekačku

Obi - krásného černouška si uvařil, jen co je pravda

Každý se musí sám bouchnout přes prsty, aby zjistil, co to obnáší.

Ted na to koukam,priznam se ale ze jsem elektrolizou nikdy nic necistil,kazdopadne cele schema by to slo postavit relativne jednoduse bez tech modulu z ciny (bal bych se to nechat zapnute bez dozoru).jako regulovatelny zdroj stejnosmerneho napeti muzes pouzit LM317,Pro vladani stridy lze pouzit bud klasicky obvod 555 kde lze zmenou odporu regulovat o stridu (plynune)nebo ho pouzit jako zdroj pro dekadicky citac 4024 kde by pak slo skokovite menit stridu 10-100% s krokem po 10%.Mozna si me nalomil a zkusim to prekreslit😉

Rovnou se přiznám jak jsem psal výše tak s elekrolýzou nemám žádné zkušenosti ,nemám tucha jestli 200mA je na stříbrnák moc nebo málo.

Každopádně LM317 snese 20W což když máš po usměrnění 20V tak je to 1A,nekoukal jsem přesně do datasheetu ale bude tam nějaký Udrop jako u klasických stabilizátor což býva u výkonovejch cca 2V takže víc jak 18V z toho nedostaneš, že to bude topit neva 20W ještě není tak hrozný,připlácneš k tomu kus hliniku a bude

Samozřejmě v podstatě s mimimálníma ztrátama pokud budeš chtít regulovat výkon tak to můžeš spínat třeba střídou 50% a hodinovej výkon budeš mít taky 50%.Změnou střídy pak můžeš regulovat výkon (PWM).To lze udělat jak přes 555, nebo použít 4060 jako zdroj frekvence a za něj hodit 4024 a regulovat střídu 10-100% s krokem po 10%

Nebo lze použít MC34063 (jak jsi psal) zapojit ho jako step down měnič a doplnit ho nějakým vykonovým tranzistorem -což je asi technicky nejčistější řešení a ztráty budou nejmenší (myslím že učinost byla okolo 80-85% ale nemám ten datasheet v hlavě)

Ale hlavně jsem nepochopil (nemám s tím zkušenosti a nikdy jsem to nezkoušel) jestli je nějak zásadní to spínat nějakou frekvenci a regulovat střídu pro to samotné čištění nebo se to dělá jen pro regulaci výkonu.

Dál by určitě šel vymyslet právě přes 4060 a 4024 nějakej časovač že by to třeba jelo v systemu 10sekud zapnuto pak 50 sekund vypnuto aby se případné části krusty stačili odplavit a takhle dokola, popř by se to třeba po 20minutách vypnulo šlo by to zobrazit i na displej-použiješ akorát 4026 a z toho můžeš rovnou krmit 7 seg. displej.

Hezky pěkně všechno analog -žádný arduino :D

Když mě napíšeš by to mělo přesně vypadat můžu to zkusit nakreslit

Já osobně bych to postavil součástku po součástce (jsem mírně nedůvěřivý k práci soudruhů z Číny, zatím toho krom reverzního inženýrství moc nepředvedli  )

)

Jako ochranu muzes pouzit tzv vratnou pojistku vyrabi se na xhodnot proudu rychle i pomale.

U 555je trochu problem ze pokud zmenis jeden z odpodu tak zmenis stridu ale i frekvenci,takze by jsi musel mit regulovatelne oba (strida je zavisla na pomeru tech dvou odporu) ale zaroven to ovlivni frekvenci protoze prez ne nabijis ten kondik.Ale zase nevim a nemam zkusenost jak moc je to tady zasadni

Pokud chces absolutne presnou frekvenci tak to muzes ridit krystalem v zapojeni 4060 ten obvod zaroven funguje jako delicka takze na vystupech mas vzdy 2xvydelenou frekvenci krystalu.Kdyz za to hodis 4024 tak podle toho kolik propojis vystupu budes mit stridru 10-100% a frekvence se ani nehne

Ted koukam ze u 555 to jde jeste zapojit pred dve opacne orientovany diody,kde to pres jednu nabijis a druhou vybijis v tom zapojeni ti to frekvenci neovlivni

Mel jsem porad v hlavne to zakladni schema s dvema odporama a kondikem